A differential band brake has brake drum of diameter 500mm and the maximum torque on the drum is 1000 N-m. The moment M f of the frictional forcef𝑁 about the hinge pin at A is.

Brake Design And Calculation Pdf Brake Vehicle Technology

If the thickness to diameter ratio tD ratio.

. When a driver applies the brakes the lining pushes radically against the inner surface of the drum and the ensuing friction slows or stops rotation of the wheel and axle and thus the vehicle. 31 Brake Factor Calculation. F coefficient of friction.

Friction devices wordpress com pdf design and analysis of fsae brake system using how a brake system works hs karlsruhe lifeboat launching gravity davit dspace at cochin analysis and design of a gear shifting mechanism for maximum brake force calculations for drum brakes brake band view specifications amp details of brake bands how to. Brake design plays an important role in heat transfer like. The solution should be applied with low pressure to prevent dust from becoming airborne.

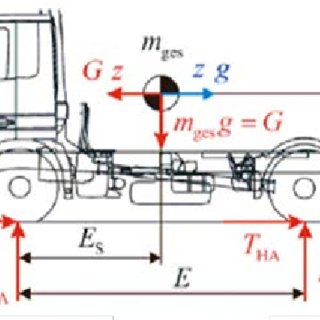

Based on the brake factor calculation derived by Mahmoud 13 for the simplex. Design requirements R BRAKE FORCE AT FRONT BRAKE FORCE DISTRIBUTION DIAGRAM UNLADEN CONDITION LADEN CONDITION. The calculation is carried out for the worst condition that is with trolley with full load at 10m.

Brake factor computer software input and out put diagrams are illustrated for a typical S-cam-brake design in Figures 2 and 3. Brake Design and Calculation - Free download as Excel Spreadsheet xls PDF File pdf Text File txt or read online for free. 53 DESIGN AND ANALYSIS OF BRAKE PEDAL Brake Pedal material 6061 Aluminium Mesh quality.

Brake design and calculation cylinder dia. Internal Drum Shoe Brake Design Equations. Brakes used can be of Drum or Disc type.

The max torque of the mechanism is. The brake service adopted is a doble shoes drum brake with electohydrailic thrustor. If the band brake is lined with asbestos fabric having a coefficient of friction 03 then design the steel band.

DRUM BRAKE SYSTEM F ma. Brake drum the brake drum is generally made of a special type of cast iron that is heat-conductive and wear-resistant. Drum brake the value of the brake factor for this existing drum brake is.

𝟒 𝐢 𝛉 𝐱 𝟒 𝛉 𝛉 𝛉 𝛉 The torque applied to the drum by the brake shoe is the sum of the. A drum brake is a brake that uses friction caused by a set of shoes or pads that press against a rotating drum-shaped part called a brake drum. Drum brake designs have at least one leading shoe which gives a servo-effect.

PC-BRAKE FACTOR software computes the brake factor of many different drum brake designs. P average contact pressure. Heat Generated p Ac f V 778 Btumin Where.

Phosphate water-based detergent to wash the brake drum or rotor and other brake parts. The green line represents the total brake factor of the leading-trailing S-cam brake. 49 0 252KB Read more.

Br sinθ max θ 2 sinθ r c cosθdθ θ 1 𝐱. Important to understand action force and friction force on the disc brake new material how disc brake works more efficiently which can help to reduce the accident that may happen in each day6 IV. For example for a lining-drum friction.

The permissible stress is 70 MPa in tesnion. Allow the solution to flow between the brake drum and the brake support or the brake rotor and caliper. VEHICLE DATA REQUIRED FOR CALCULATIONS GVW -Laden Front Axle weight Kg if provided 12592 Calculated 12592 Rear.

19 0 168KB Read more. V peripheral velocity of drum. In an Inboard braking system the rotor brake disc.

The supply and the design have to comply with the technical specification of the. Ac contact area in². CALCULATIONS 41 Overview of Design The braking system uses a front rear split braking circuit.

So there is a need to design a new brake disc system which can stop the vehicle without skidding and within a short distance. WHEEL CYLINDER Wheel cylinder or caliper pistons. Aircraft brake systems perform multiple functions.

M f fdN r ccosθ fp max. The equations needed to design a braking system are not difficult to derive but this page is a reference to most of them. It is assumed that the out of balance opposes the action of the brake.

Mechanics and Machines Calculations Menu. Drum brakes depending on certain advantages discussed below. If the load is at rest the static brake.

The calculation for the heat flux is done by the relations given in the brake design and safety by Rudolf Limpert. Is it required to design a peripheral brake disc system and needs optimize it for. Disc brake is the recent trend in automobile vehicles which dissipates the heat faster than the conventional drum.

Usually Disc brakes. Maximum brake force calculations for Drum Brakes Anirudh L Subramanyam Sandeep Banik The maximum brake force that can. Most of the vehicles use hydraulic braking system while some light vehicles such as bicycles use brake wires.

By contrast a disc brake has no self-. DESIGN CALCULATION OF DISC BREAK ROTOR Here presenting the work for disc brake of MARUTI Company for stress reduction studies. The term drum brake usually means a brake in which shoes press on the inner surface of the drum.

It rotates with the wheel and axle. Basis of Brake Calculation Basic braking calculations are derived from simple. Double Shoe Brake.

Depending on the position of rotor the braking system is of two types - Inboard Braking System and Outboard braking system. Drum diameter reel diameter etc The brake will need to overcome this load before it can start to slow down the machine. Brake holding test The brake secures the drum and thereby the mooring line at the.

Maximum brake force calculations for Drum Brakes Anirudh L Subramanyam Sandeep Banik The maximum brake force that can. Force on each brake drum F4 36449 N Area of the shoe brake in contact with brake drum 2 9423 30 106 565 103 Pressure on the brake drum FA 3645 565 103 0645 MPa To calculate the stress in the Brake Drum by the application of pressure. We will look at each of these functions separately.

Brake Calculations There are many books on brake systems but if you need to find a formula for something in particular you never can. The brake embraces 23. They must be able to hold the aircraft back at full static engine run-up provide adequate control during ground taxi operations and be able to effectively stop the aircraft during landing and roll-out.

Brake Design and Calculation. The wheel hub and brake assembly components should be. Mooring Winch Brake Capacity Calculation.

BRAKE SYSTEM DESIGN AND THEORY.

Internal Drum Shoe Brake Design Equations And Calculator Engineers Edge

Viewing A Thread Good Article On Custom Brakes Disc Brake Conversions

Drum Brake Calculation Pdf Brake Vehicles

Pdf Detailed Strength Analyses Of Drum Brakes Used In Light And Heavy Duty Trucks

Contact Analysis For Drum Brakes And Disk Brakes Using Adina Sciencedirect

0 comments

Post a Comment